Processing / Extraction

Solvent / Non-Solvent

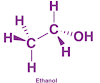

Cannabis compounds are hydrophobic -> do not dissolve in water.

Alcohol and hydrocarbons (like butane) are two solvents that can dissolve oily compounds like those from cannabis.

CO2 can be used as well as solventless methods. All are shown below!

**Commercial Grade Closed Loop Extractors: https://precisionextraction.com/**

------ Cannabis Extraction Chemistry:::::

NO RESIDUAL SOLVENTS. Nonflammable process; non-toxic solvent with purity of final product; CO2 recycling significantly reduces carbon footprint & CO2 storage.

Hydrocarbon extraction -(BHO PHO HHO IHO etc): Explosive, hard to remove solvents

Best Hydrocarbon results: Shatter, or crystalline/diamond structures, or after further distillation, and color remediation to produce the orange/gold colors. Taste is often devoid of terpenes and product can be unsafe, and best used as an ingredient in edible products. Both physical and environmental factors can influence what the final extract sets up to look like and what texture it will take on. (Shatter vs wax)

++++

FLASH CURE / Sublimation:

Sublimation Freeze Dryers for curing Flower to Smoke / vaporize - not the same as a Live Resin frozen extractions, but frozen cured product can be used for Live Rosin Presses and other Extraction techniques -- like CO2 / Hydrocarbon / etc.

This process can preserve buds and terpene profiles better than standard curing because they don’t use heat.

Because of the quick cycle and controlled environment, there’s reduced risk of mold or mildew.

Growers/processors working with concentrates like hash and shatter find the units to be extremely useful.

"Cryo Cure" - patent-pending cannabis drying and curing process gives harvested cannabis that “fresh from the farm” feeling, preserving the color, smell, and texture lost during the typical weekslong curing process. https://cryocure.com/how-it-works/

Salt Lake City’s Harvest Right has freeze-drying units that shorten the curing process to just 24-36 hours. Rosin press company "Pure Pressure" is a reseller of theirs and has even won awards using Harvest Right’s freeze-drying machines.

++++++++++++

Weed Diamonds:

Crystal "diamonds" require some seriously heavy-duty machinery, as well as expertly handling some incredibly toxic and volatile solvents.

Only certified pros should attempt this in a regulated lab with extensive safety measures in place.

Step I: Make hash oil using a live cold-extraction method. The goal is to ensure the THCA does not convert to THC as a result of the extraction process. THCA will crystallize under the right conditions; THC will not.

Step II: Put the oil through a winterization process, which is just mixing the oily extract with Everclear, freezing it, then filtering the product.

Step III: Soak the winterized hash oil in a methanol liquid before using a rotary evaporator (or rotovap) to remove the methanol.

Step IV: Wash the oil in a pentane solution to remove any remaining plant matter residue. Run the rotovap again.

Step V: Here’s where the chromatography machine comes into play. It essentially puts pressure on the oil that compounds it into crystalline form.

Step VI: Allow the diamonds to dry for three to 12 days.

Viola! That’s the secret to weed diamonds. Again, this a process best left to expert professionals -- several brands currently offer THCA crystals for sale in US markets

++++

Sublingual cannabis - "Kin Slips"

Sublingual strips. Also referred to as thin-film drug delivery, sublingual (literally translating to “under the tongue”) strips neatly and efficiently deliver cannabis directly into the bloodstream while promising a consistent experience by completely bypassing the digestive system.

“There’s a number of different ways that extractions work and we use a couple of specific types.” continues Kirby. “Ethanol or CO2 extraction work basically the way any other solvent extraction would work: You take your cannabis and you either freeze it or pulverize it, then you flood it with the solvent. So, you would either kind of just dump a bunch of ethanol into it or put it into a specialized container that lets liquid CO2 travel through it.”

Kirby goes on to explain how his team isolates terpenes and flavonoids, which are then stripped out of the solvent and extracted, leaving a crude oil called the distillate.

+++++

LIVE "ROSIN"

"HEAT PRESS"

"HEAT PRESS"

https://www.thegrowthop.com/cannabis-culture/what-is-rosin-exploring-the-purest-cannabis-concentrate

What exactly is Rosin? (not Live Resin!): https://precisionextraction.com/2020/12/extracts-live-resin-vs-rosin/

Rosin is a cannabis concentrate made through an extraction technique that manipulates fine hash using pressure and heat. Having a very high cannabinoid and terpene concentration, rosin is further differentiated from other concentrate products because of several important factors. The first is overall purity, the result of using only heat, pressure and sift bags with microscopic openings—as opposed to any solvents—to separate cannabinoids and terpenes from the plant. Rosin won’t have any solvent residue, while other techniques may require going through more steps to purify the concentrate, something not always fully achieved.

++++

BUBBLE HASH:

ICE HASHISH AND HOW IT IS MADE

(Water only, non-solvent filter extraction)

++++

LIVE "RESIN"

Live resin is freshly harvested cannabis frozen to a subcritical temperature (see: freeze drying sublimation) prior to and throughout the extraction process.

Live resin concentrates are able to capture the flavors and aromas of the living plant through extraction, compared to other types of cannabis concentrates. Live resin is relatively new to the cannabis concentrate scene. William Fenger (also known as “Kind Bill”) and EmoTek Labs founder “Giddy Up” pioneered the live resin extraction process by developing a specialized BHO extractor capable of maintaining the incredibly low temperatures needed to produce live resin.

++++

Winterization

The winterization process starts with raw extract -- sometimes best straight from a CO2 machine.

This crude oil contains all the essential parts of the hemp plant except for the actual plant material itself. CBD/THC, minor cannabinoids, terpenes, fats, waxes, and lipids are all part of this viscous liquid.

This crude oil contains all the essential parts of the hemp plant except for the actual plant material itself. CBD/THC, minor cannabinoids, terpenes, fats, waxes, and lipids are all part of this viscous liquid.

Crude oil extracted from a CO2 machine will have an attractive, light color to it, especially compared to alcohol extracted oil, which will have a dark, sludge-like appearance.

How does winterization work?

The crude oil is finally combined with 200 proof alcohol (ethanol) and stirred vigorously until completely mixed. The alcohol is used to thin the crude oil out, as the desirable parts of crude will go into solution with the alcohol while the undesirable parts will coagulate and freeze allowing them to be filtered out.

The mixture is then placed in a deep freezer at below-zero temperatures;Once it has time to freeze it looks cloudy and is ready for filtration.

Next step is to place the mixture in vessels that use paper filters to remove frozen fats, waxes and lipids.

The actual oil remains with the alcohol solution, and passes through the filter while the frozen undesirable parts are caught by it.

++++++++

+++++++++

Color Remediation:

Color remediation, (also used in Wine Making), is the use of adsorbent medias to target certain compounds in conjunction with one another to remove as many impurities as possible with a single pass.

The media must not become over or under saturated.

Over saturation of your media means that impurities will pass through without being filtered.

Under saturation of the media will cause the media to retain cannabinoids resulting in a loss of yield.

Using the right ratios of magnesium silicate and silica gel will take winterization completely out of the extraction process!

The following technique for color remediation works for just about every single unwanted compound from your extracts. This works with Butane, Ethanol, and Hexane. It is slightly more effective with Alkanes due to their non-polarity and the polar attractant nature of the filtration medias, but these medias are still more polar than ethanol -- resulting in them still working, just less efficiently.

When using hexane or ethanol as solvent, primary goal during experiments was to remove as many impurities as possible while creating a crude oil that required no pre or post processing (before or after a first pass distillation).

This authors' priorities regarding butane focus on remediating as many impurities as possible resulting in a high clarity, low color shatter, even from older material, and was able to achieve both goals.

The ratios and amounts of media will change based on quality and freshness of material, the solvent being used, and amount of material used.

I will try to give ratios for each solvent and freshness of material.

NOW ONTO THE TECHNIQUE!

I will explain briefly what each media targets.

-Activated Magnesium Silicate

Activated magnesium silicate has the perfect pore size to grab lipids. This makes it a prime candidate to be the very top media in your stack. If your method of extraction brings along any lipids, removing them first with magnesium silicate will make all the rest of the medias much more effective.

-Activated Silica Gel

Activated silica gel adsorbs chlorophyll, carotenoids and other hydrophyllic impurities. These are your dark greens and oranges. Silica Gel does the heavy lifting for remediaton of very dark colors.

-50/50 PVPP/Activated Carbon blend

Polyvinylpolypyrrolidone (PVPP) Is an adsorbent that removes tannins, polyphenols, and oxides. These include many of your more red colors. Activated Carbon helps grab any remaining chlorophyll and allows the PVPP to flow better since it is an extremely fine powder prone to clogging. I generally blend even volumes of both powders before packing, no one sells this pre-blended that I know of.

-Activated Bleaching Earth

I buy my activated bleaching earth from Anovia Group. It’s the best bleaching earth I’ve had the pleasure of using and priced very competitively. It has worked better for color remediation than t-5 or t-41 and is much cheaper. Activated bleaching earth is the final filtration media and is used last when all impurities have been removed and you are just trying to lighten the color of your extract and remove any remaining pigments.

-A7 Proprietary Media

This is a media a friend developed and is beginning to sell. I had the pleasure of testing this for him and loved it. This media is optional and would be the final step if you choose to use it. This is a good adsorbent treated with a lewis acid. The lewis acid helps convert cbd to cbn. The use for this media is for people who are going for ultimate thc purity on first pass. By converting cbd to cbn it allows the cbn to be distilled into the tail fraction instead of the main body, which gives you a higher thc purity.

– Celite 545/Diatomaceous Earth

Simple filter aid that keeps your medias from clogging your filter papers or sintered filter

Calculating ratios:

The best way to calculate ratios is to estimate how much finished oil your material will produce. Weight of material being processed multiplied by the percentage of cannabinoids available.

For example a ten pound run of material (4480 Grams) containing ten percent cannabinoids would produce an estimated 448 grams (4480*0.1).

From this estimated yield we can calculate how much media to use without over or under saturating the adsorbents.

-Magnesium Silicate

For BHO

Fresh material 40% of estimated yield

Old material 55-60% of estimated yield

For EHO

Fresh material 60-65% of estimated yield

Old material 80-85% of estimated yield

For HHO(hexane) extracted at room temp

Fresh material 80% of estimated yield

Old Material 100% of estimated yield

-Silica Gel

For BHO

Fresh material 20-25% of estimated yield

Old material 40-50% of estimated yield

For EHO

Fresh material 40-50% of estimated yield

Old material 60-80% of estimated yield

For HHO

Fresh Material 200% estimated yield

Old Material 300-400% estimated yield

-50/50 PVPP/Activated Carbon

For BHO

Fresh material 40% of estimated yield

Old material 60-70% of estimated yield

For EHO

Fresh material 80% of estimated yield

Old material 120-150% estimated yield

For HHO

Fresh material 50% of estimated yield

Old material 80% of estimated yield

-Activated Bleaching Earth

For BHO

Fresh material 10% of estimated yield

Old material 25% of estimate yield

For EHO

Fresh Material 15% of estimated yield

Old material 30% of estimated yield

For HHO

Fresh material 5-10% of estimated yield

Old material 20-25% of estimated yield

-A7 media

For BHO

Fresh material 2% of estimated yield

Old material 5% of estimated yield

For EHO

Fresh material 5% of estimated yield

Old material 10% of estimated yield

For HHO

Fresh material 2% of estimated yield

Old material 5% of estimated yield

Now --> time to build a filter stack

-Flow Considerations

How fast you’d like to complete a cycle and how much material you are running per cycle will decide the width of your filter column. In my experiments with 10 pound runs, a single six inch column sufficed and allowed me to complete a cycle in two hours. A simple way I’ve found to estimate the necessary column width is to start with 10 pounds being a 6 inch column and every time the weight doubles add 2 inches to the filter width, so for a 20 lb cycle an 8 inch column would be good, for a 40 lb cycle you would want a 10 inch column, and for an 80 pound cycle you would want a 12 inch column.

-Packing the column

Packing your column correctly is mandatory. An incorrectly packed column will have channeling and improper flow. Improper flow means improper adsorption by the media.

To pack my columns I set up the filter plate either with a 5um bottom paper and a 25um top paper or with a 4um sintered filter depending what is available to me.

I then put a reducer on the bottom of the filter plate and the spool on top and attach it to a vacuum.

I slowly add media while tapping the sides of the spool very hard with a 1 pound rubber mallet.

I then use a flat cap to pack the layer down as flat as possible.

Then I use a mesh screen with a drop in filter plate on top of the layer to press it with a hydraulic press and make it completely flat and even.

I have had success without the press, just using vacuum, many times but there was still the occasional channeling, since using the press I haven’t had any channeling issues.

Slowly and carefully remove the drop in filter plate and mesh screen, as not to disturb the layer, and start on your next media following the exact same procedure.

It should be packed in this order first to last, bottom to top: Celite/DE is your first and bottom layer always so you don’t get clogs.

Next layer would be A7 media if you choose to use it.

After that would be your Activated Bleaching Earth.

Next is your 50/50 PVPP/AC blend.

After that Silica Gel, and the final and top layer is your magnesium silicate.

I always cover my last layer with a filter paper and ring so that the solution doesn’t disturb the layering when you open your valves.

You want a valve at the bottom and the top of your filter stack.

-The Process

Now we’re to the fun part, extracting the material.

All BHO and EHO extractions were done at cryogenic temperatures. -60c or lower.

HHO(Hexane) extractions were done at ambient temperatures around 70f.

You will need two collection bases with at least one jacketed for this process.

Your system should be hooked up:

Material Colums-->Jacketed Collection Base-->Filter Stack-->Collection Base-->Recovery System.

Blast material normally into your first collection base.

If using Butane or Ethanol, run 26-30c thermal transfer fluid through your jacket until the solution reaches the same temperature as the jacket.

Once solution is ambient temperature slowly open the valve at the bottom of your collection base and the valve at the top of your filter stack.

Leave the bottom valve on the filter stack closed. Wait about ten to fifteen minutes for the solution to slowly evenly and fully permeate all layers of the filter stack.

Once all layers have been permeated turn on your recovery system and open the valve to your second collection base, then slowly open the valve at the bottom of the filter stack about half way. you need to choke the flow at the bottom side of the filter stack to help avoid channeling.

One thing that is a bit wasteful but gives me great success when using butane is setting the blow-off valve on the first collection base to 20 psi so there isn’t as much back pressure to create channels, but this does waste quite a few pounds of solvent.

Using hexane or ethanol just don’t pressurize over 20 psi with your nitrogen.

Recover all your solvent and either throw it in the vacuum oven, or go straight to distillation.

+++++++

LAB MATERIALS:

No comments:

Post a Comment